A carbon cleaning equipment specially designed for vehicle repair shops.

Basic benefits

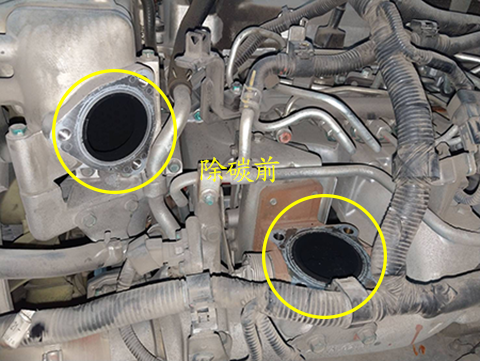

Prior to carbon cleaning, the condition of EGR (Exhaust Gas Recirculation) cooler and throttle valve's carbon deposits.

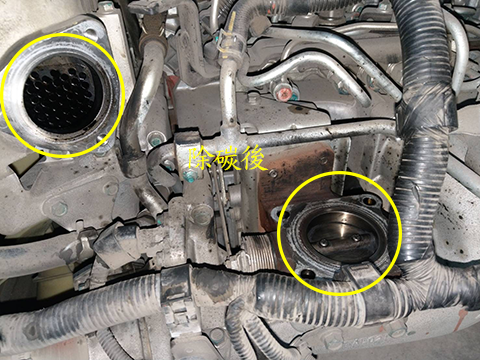

After carbon cleaning, the condition of EGR (Exhaust Gas Recirculation) cooler and throttle valve's carbon deposits.

Before decarbonization, observe the carbon buildup inside the cylinder using an endoscope.

After decarbonization, observe the carbon buildup inside the cylinder using an endoscope.

Correct, the removal of carbon deposits at various levels may require special treatment depending on the situation. The differences observed before and after carbon cleaning, as mentioned earlier, are individual case references and do not necessarily represent the same outcome for all cases. Each situation may vary, and a tailored approach might be necessary for optimal results.

Our documents will provide recommendations based on the best knowledge available. However, the content is not legally binding for processing and application as these are beyond our control. We reserve the right to make modifications for improvement or progress.

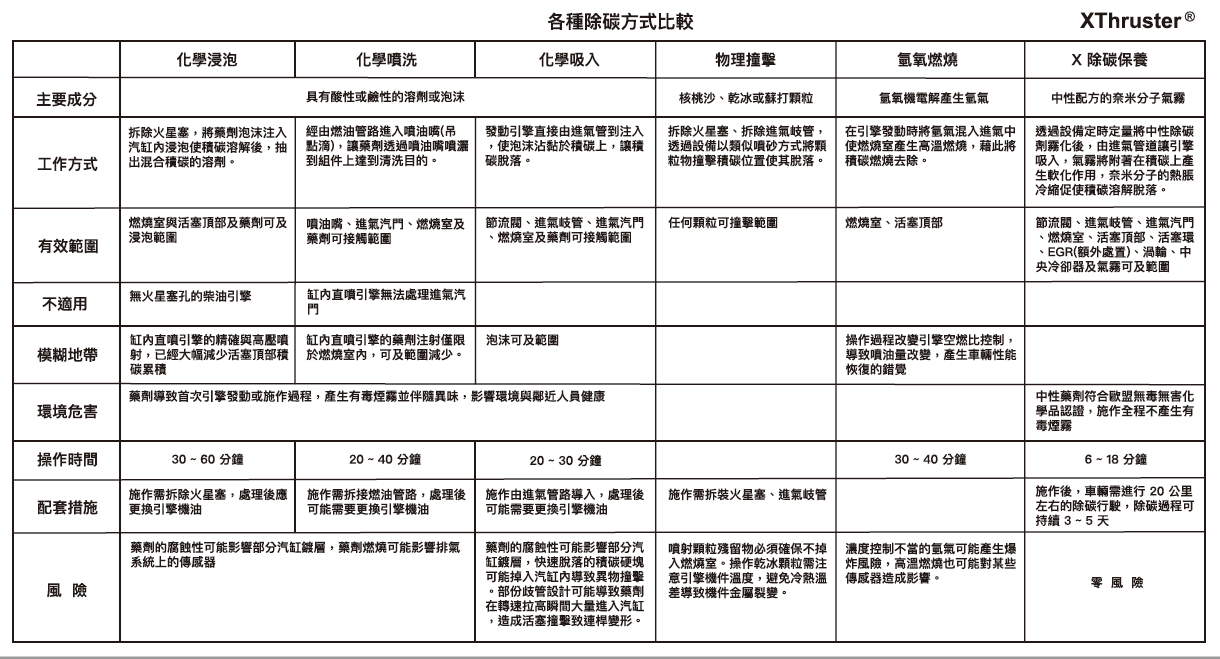

This is the X Carbon Cleaning Equipment, a series of products from XThruster®. We have meticulously designed this exceptional carbon cleaning device specifically for vehicle repair workshops. The main feature of this equipment is the ability to remove carbon deposits from the engine during maintenance without the need for complex disassembly. This innovative solution allows you to perform carbon cleaning on engine components with minimal disassembly steps, all while ensuring no secondary pollution is caused.

This equipment uses a variety of carbon removal agents formulated with Nano scale oxidation mixtures, and is matched with a programmed X carbon removal machine. Vehicle repair shops can choose appropriate carbon removal modes based on different engine types and carbon accumulation conditions. This allows the X Carbon Removal Machine to perform precise and quantitative carbon removal procedures in a preset mode.

Our nano-scale oxidizing mixture consists of extremely fine molecular particles. Upon introduction into the intake system, it can gently remove carbon deposits from various components, including throttle valves, intake manifolds, valves, cylinders, piston rings, EGR (Exhaust Gas Recirculation) system, and EGR cooler. The carbon removal agent’s mist-like molecules can adhere to surfaces throughout the system, producing an effective carbon cleaning effect.

The X Carbon Cleaning Equipment aerosol supplied by the The aerosol molecules are discharged through the exhaust system.

During vehicle maintenance, the use of strong acidic or alkaline chemical foams may cause carbon deposits inside the engine to detach in a ‘block-like’ manner. These ‘block-like’ carbon deposits could enter the engine’s combustion chamber, collide with pistons and valves, and subsequently lead to valve damage and insurance disputes.

The X Carbon Cleaning Equipment uses a quantified mist of nano-decarbonizing agent, which can gradually soften and detach carbon deposits without the risk of ‘block-like’ detachment. Paired with a decarbonizing drive of approximately 20 kilometers, this allows for a safe and effective completion of the decarbonization process.

Our carbon removal agent is safe and harmless, complying with the European Union’s REACH regulations, ensuring it is non-toxic and poses no harm. Its usage does not lead to public nuisance, and it does not have any adverse effects on the health of the workers or the environment. Furthermore, its safe characteristics prevent any corrosion or damage to the internal coatings of cylinders.

All engine operations will produce carbon deposits, and regular removal is necessary. The X carbon remover provides a fast, safe, and disassembly-free carbon removal method, making the carbon deposit removal process simpler and more efficient, reducing the time required for engine component disassembly and cleaning, and avoiding component damage that may be caused by the disassembly process. risk.

Overall, our X Carbon Remover is your ideal engine cleaning solution. It will bring huge benefits to your workshop in saving time, increasing efficiency and reducing risk. When you choose our products, you choose a safe, effective and economical choice.

Carbon removal mode options:

Locomotive 10ml/5min

Gasoline vehicle 30ml/6min

Diesel vehicle 60ml/12min

Large diesel vehicle 120ml/24min

Heavy diesel vehicle 150ml/30min

Carbon cleaning agent barrel capacity: 800ml.

Voltage: AC 100-240V / 33 mA-16mA / Power 4W.

Volume: 340 x 203 x 227 mm / Weight: 5kg.

To contact us directly, please add Line official account to inquire and express your needs.